Applied Film

Description

State-of-the-art applied window films are designed to improve window performance by rejecting temperature increases from sunlight (solar heat gain), protecting against glare and ultraviolet (UV) exposure, offering a wide range of choices in the amount of light transmitted through the window (visible transmittance or VT), and in a few cases, increasing thermal insulation. Window films typically cannot be adjusted or readily removed. Because of the range of film types, there are products that are useful in almost every climate and for every window application.

Window films can be professionally applied by a skilled installer or are available for do-it-yourself projects at home improvement stores. Films are typically about 2–7 mils thick (50–175 microns) and come on rolls 36 to 72 inches (1–2 meters) wide. Films have a minimum of three layers: a pressure-sensitive or water-activated clear adhesive layer (against the glass), a polyester film layer, and a scratch-resistant coating. Films for safety/security function will be substantially thicker. A variety of other technologies that tune the film for different performance properties can be added to this basic configuration: tints, low-emissivity (low-e) coatings, and UV radiation blockers. Spectrally selective low-e coatings are preferred because they block some portions of the sunlight spectrum to reduce unwanted solar heat gain while allowing other portions of the spectrum to pass through the window, which maintains visibility. Some films absorb, rather than reflect, solar radiation. This reduces their effectiveness because the absorbed energy will heat the glazing surface and a portion of that energy will be transferred into the room. If the film is applied to the interior side of a window, this residual heat will be greater, negatively affecting the comfort for those in the room.

Rapidly developing window film technologies include low-e, thermo-chromic (changing transmittance with temperature),

and electro-chromic (changing transmittance with an electric current) window films.

Overall Thermal Performance

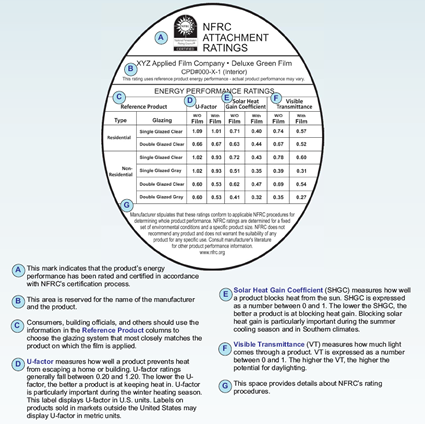

For a specific application, users can assess the amount of solar heat gain through a window with film based on the solar heat gain coefficient (SHGC) and visible transmittance (VT) rating listed on the film’s National Fenestration Rating Council (NFRC) label (see page 1). Window films were the first—and so far only—window attachment option to be rated by the NFRC.

Key Benefits

- Reduce solar heat gain through windows (many different films are available with widely varying solar heat gain rejection properties)

- Reduce heat loss when low-e coating is applied as the innermost exposed layer of the film

- Reduce glare and eye strain (some films are designed specifically for these benefits)

- Block UV very effectively (95-99.9%)

- Provide privacy (films with high reflectance or “mirroring”)

- Enhance security and safety (some films designed specifically for these benefits)

- No operation or maintenance

The window on the left has no film; the window on the right does. How much a film alters the appearance of the window (inside and out) depends on a number of variables and is difficult to generalize because there are currently so many different films.

Photo: Eastman Chemical Company

Key Drawbacks

- Undesirable interior “mirroring” with interior films that have high reflectance

- Reduce winter solar heat gain (in heating-dominated climates)

- Increase condensation potential when low-e coating is the innermost exposed layer of the film

- Higher-absorbing films will reduce energy savings and decrease comfort

- Do not reduce air leakage

- May increase need for electric lighting (films with lower VT)

- Once installed, require special procedures and release agents to remove (should be done by professionals only)

Aesthetics

- Darkening of windows (degree of darkening dependent on product; higher-VT films result in almost no change in light transmitted)

Tips/Cautions

- Look for an NFRC rating label for solar heat gain coefficient (SHGC) and visible transmittance (VT); manufacturers can provide other performance data, such as UV blockage, U-factor (indicates rate of heat loss), glare reduction, and security functions.

- Look for transferable lifetime warranty.

- Having a professional install or remove film is recommended.

- High-VT films and some films with spectrally selective low-e coatings result in minimal change in transparency or appearance.

High performance applied film in production being inspected for defects. Note the series of lamps that help in assessing film quality.

Photo: Eastman Chemical Company

Applied window films can be installed by do-it-yourselfers, but professional installation is recommended. After thorough and specialized cleaning, the installer will apply a solution to the window surface prior to rolling and squeegeeing the film.

Photo: Eastman Chemical Company

When To Consider

- Solar gain through existing window results in overheating or uncomfortable glare.

- Homeowner does not want to block key views with awnings or other window attachments that interfere with view.

- Home has large areas of glass that would be prohibitively expensive and/or awkward to replace or treat with other retrofits such as storm windows or insulating blinds.

- Homeowner is concerned about UV fading of artwork and furnishings near windows.

Where to use

- Sunny, clear-sky climates: medium to low SHGC and VT films

- Non low-e products: climates with moderate to significant cooling requirements

- Low-e products: all locations

When to consider this retrofit—Ownership

| x | Homeowner |

| Apartment Renter – Long Term | |

| Apartment Renter – Short Term | |

| x | Live in a Condo* |

| x | Live in a Historical District* |

* Condominium regulations or historic building codes may require the use of higher-VT and lower-reflectance window films that maintain appearance from the outside.

When to consider this retrofit—Window conditions

| x | Existing window single-glazed |

| x | Existing window double-glazed, no low-e* |

| x | Existing window double-glazed with low-e |

* Applying a non-low-e surface film to a low-e window makes the most sense

Recommended Installer

| x | Do it Yourself |

| Carpenter | |

| x | Manufacturer or supplier |

Once applied, films are treated and maintained just like the original glass. Today’s state-of-the-art films are more scratch and UV-resistant.

Photo: Eastman Chemical Company

Complementary Options

Compatible with any window attachment but work best with:

- Exterior storm windows

- Window unit air sealing

Operation

None

Considerations

| 1 | 2 | 3 | 4 | 5 | |

| Ease of Installation (1 = easier) |

x | x (DIY) |

|||

| Availability (1 = more available) |

x (DIY) |

x | |||

| Cost Details (1= lower cost) |

x (DIY) |

x |

Average Total Cost for 30- by 60-inch window

| Do it Yourself | $10 |

| Standard solar control | $80 |

| Spectrally-selective | $125 |

Digging Deeper

Energy Modeling Tools for Professionals

| x | RESFEN |

| x | EnergyPlus-based modeling tools |

| x | WINDOW 6 |

| x | Other: Manufacturer web-based calculators; look for evidence that such calculators are effective, such as endorsement by Lawrence Berkeley National Laboratory |

References

“Measuring the Savings from Energy-control Window Film Installations Using IPMVP Options C and D”